Salem Home

Knowing their niche empowers this design/manufacture stronghold

Steel Grip Inc. is the first to admit that bigger isn’t always better. In terms of size, this producer of PPE (Personal Protective Equipment) is a lightweight compared to some big names in the industry, yet they are proud of their ‘small business’ status. Why? Because Steel Grip Inc. is a recognized domestic and international leader in their ‘niche’ market of specialized protective wear. For over 30 years, Steel Grip has built priceless relationships with employees, distributors, suppliers, and customers into a network based on trust that continues to thrive in an ever changing industry.

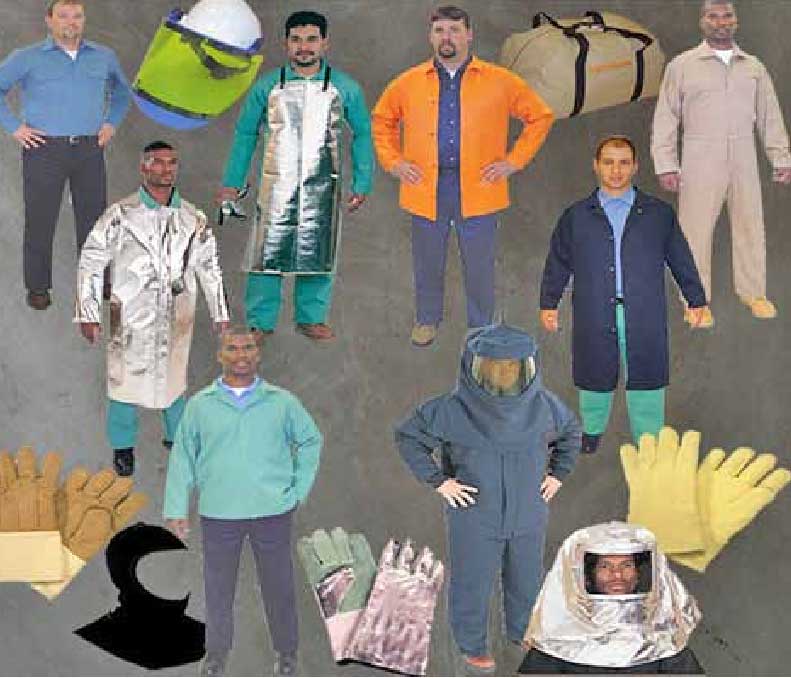

Headquartered in Danville, Illinois, with separate manufacturing facilities in Covington and Kingman, Indiana, Steel Grip Inc. designs and produces industry-specific attire, such as electrical protective clothing and high temperature protective apparel. Exclusive lines include over 3,000 products essential for head, body, hand, leg, and foot protection in a variety of work environments.

Meeting customer needs and stringent safety regulations, while enhancing quality, lowering costs, and achieving competitive product performance keeps the Steel Grip team focused and busy throughout. To these talented professionals, the potential life-saving results of their work is the ultimate reward for a job well done.

Back story

Steel Grip was incorporated in the mid-1980s, Jeff Mason (President), Bob Brewer (VP Director Corporate Sales) and Mike Stultz (Sales) are still actively involved in the corporation. Together, the trio provides a wealth of experience in sales, marketing and corporate strategy that they share.

“The customer base was already established when the new owners took over,” Mason says, “and we grew it from there. We worked hand in hand with the existing distribution network and responded to circumstances and opportunities as they arose. We still provide this type of customer service today.”

“Back then,” Brewer adds, “federal regulators were becoming prominent in this industry, as far as creating rules and guide lines for personnel within a potentially hazardous area. The family that purchased this company had the foresight to see that this was an up-and-coming, evolving market. That was the main stimulus then that moved Steel Grip into the industrial apparel markets.

Physical Operations

Logistically speaking, having three manufacturing facilities within a 20-mile radius of each other is brilliant. Each plant focuses on certain products, yet interfaces with the others. One makes shirts and jackets, as well as, high temperature gloves and mitts; the second produces industrial pants and coveralls. The main Danville site does custom-made specialty items such as aluminized apparel and leather products. But, they all feed the same industry with regards to personnel protection against potentially hazardous industrial environments.

Five major sectors comprise the Steel Grip customer base – aluminum, steel, electrical, oil and gas. “The automotive and chemical fields are also good,” says Stultz. “We try to stay diversified; if the oil market goes down, we watch those orders decline and hopefully other sectors will stay strong. The electrical industry has been steady for 15 years and probably will stay strong for another 15 years.”

Brewer notes, “We are also diverse in our capabilities of creating customized products. We’ve been approached by many domestic and international distributors to develop custom built speciality apparel, so we are flexible when markets demand. Our daily focus is to convert raw speciality materials into finished personal protective equipment and apparel. Our creative manufacturing ability has been our long established strength that has sustain our customer relationships throughout the years.”

Theory of Evolution

“Industries are evolving, especially in metals,” says Stultz. “Foreign conglomerates buy US aluminum and steel manufacturers – bringing in new technology which requires a change in safety garments. These companies prefer to use materials from Europe. That adds a whole new level to manufacturing, but many domestic apparel companies don’t want to get involved with importing and stocking materials. When a foreign company buys a local aluminum mill, those people still like to buy American garments, so we bring in what’s necessary to supply them.”

Distributors buy product from Steel Grip and resell them to the end users. With such a technically complex product line, they rely on our sales team to answer questions, often asking them to call the customer directly. Stultz acknowledges, “It’s daunting when someone asks, ‘Hey, what do I wear for molten magnetism?’ For many distributors, we are their first call.

So why not cut out the middle man? “Our valued distributors are out in their regions every day. They have the presence and the relationships already formed. We have seven sales representatives that cover the US and Canada. We would much rather support our distributor relationships and their sales personnel who are already connected to the customers.”

As for competition, Brewer says, “Larger domestic manufacturers can provide more competitive pricing. Most are now offering flame resistant apparel products. But they are not receptive to custom built speciality products that generate small yields. It is difficult for these larger manufacturers to create small production runs.” Being a ‘niche’ fabricator, Steel Grip is known for accommodating the ‘little’ specialty jobs, and that can translate into repeat business.

Garment materials come from key suppliers who search worldwide for raw fabrics that are then, in some cases, rendered flame resistant through chemical processes and applications. Mason notes, “We purchase these fabrics and literally cut and sew to specification. Our recently opened location in Danville has more square footage and a consolidated cutting department, so all the computerized cutting takes place here in one facility. The larger, fully-modernized building is also a single shipping point for our two sister plants.”

Success and Succession

Significant capital investment in their new facility was essential to Steel Grip’s long range plan: “Building for the future, and hiring for the future.” On the sales side, Stultz tells it like it is: “Our team is getting rather old. I’ve brought in five sales people in the last eight years. They need to be well trained before contacting clients. Our goal is to have this exceptional team in place within a year or two to take over and successfully manage the sales and marketing aspects.”

Steel Grip Inc. applauds its marketing and sales divisions for strengthening partner relations and sourcing new opportunities. High importance is placed on participation in national conventions and conferences. Moving forward, marketplace exposure is a priority. Being ever present in front of the right people. “You’re only missed if you’re not there.”

______________________________________

AT A GLANCE

WHO: Steel Grip Inc.

WHAT: Privately owned American company. Designs & manufactures industrial protective clothing for domestic and international applications.

WHERE: Headquarters in Danville, Illinois. Additional manufacturing facilities in Covington and Kingman, Indiana

WEBSITE: www.steelgripinc.com